Tech Committee Pages

Eliminating vibration problem in Gary Rusher's 30U Coupe

By Gary Rusher

When I first got my car going (about 6 years ago), it had a bad vibration. This vibration was related to the engine RPM only. I was not affected by speed, road conditions etc. In fact you would get a bad vibration if you were setting still and revved the engine. The vibration occurred while the engine was in compression and slowing. While decelerating from 35 to 25 mile per hour it would nearly shake the car apart.

When I first got my car going (about 6 years ago), it had a bad vibration. This vibration was related to the engine RPM only. I was not affected by speed, road conditions etc. In fact you would get a bad vibration if you were setting still and revved the engine. The vibration occurred while the engine was in compression and slowing. While decelerating from 35 to 25 mile per hour it would nearly shake the car apart.

I did all kinds of things, checked timing, (had the distributor rebuilt, as it had a loose shaft), checked for anything solidly connected from the engine to body or frame (I did find a couple minor things), even took a flywheel and clutch out and had them balanced. I found the front motor mount was bad and replaced it. STILL NO CHANGE IN VIBRATION Thought the front motor mount was it as it was bolted direct though to the frame.

I thought if the front motor mount was bad, well what about the rear ones. Sure enough the one had delaminated itself and the inside plate was sitting on the frame. I had an extra set of plates, so I took them in to a company here in Oregon and had them re-vulcanized. I took out the old motor mounts and replaced them with the rebuilt ones. STILL HAD THE VIBRATION

Over the last few years I have tried anything anyone suggested.

I took the car to the Cruise-In up to the Columbia Gorge Interpretive Center on Saturday, August 30th (about 100 miles each way) and said this is enough. I have to fix these rattles. Well after I got started trying to fix rattles I figured I would try to fix the vibration which caused the rattles.

One of the fellows in our Tech Committee had suggested that maybe the new rear motor mounts were bad. I had kind of dismissed that idea, as they were new.

If you know how the rear mounts are constructed they have a 1/2” rubber sheet vulcanized between two steel plates that have 4 carriage bolts sticking out each side for mounting to the frame and the motor. Well I took out one of the motor mounts today, and sure enough if was bad. Using an ohm meter I found that two of the heads of the carriage bolts hidden in the rubber were in fact touching.

As it so happens I had another set of motor mounts and was able to replace that one with a good one.

I took out the other side mount and it tested OK, but I replaced it anyway.

GUESS WHAT. I took it for a test drive and it was like a completely different car. NO VIBRATION Today I took it up to 50 MPH, previously only dared go to 45 due to vibrations and rattles.

After so many years of fighting it, I think I finally won.

The moral to this story is simple. Just because you just replaced it, doesn’t mean it can’t be BAD.

P.S. I still have a slight engine vibration, probably caused from having the clutch and flywheel balanced. Guess I will still have to pull the engine down and have the crank, rods, pistons and clutch and flywheel all balanced as one unit.

___________________________________________________________________

Gary Rusher's U-Joint Upgrade

(1928-1930 Plymouths utilized a flexible disk instead of a universal joint. Gary Rusher describes an upgrade he recently installed in his 30U Business Coupe.)

By Gary Rusher

I just got this done on my 30 and hope it works out.

I had contemplated replacing the disks in my 30U Business Coupe and finally found some. They were 5 that were left over from a job that a company in Portland, OR had done some years ago. After I got them I was concerned that they were not machine made and it appeared that they might not balance really well. At that point I decided to look at my options of installing new style U-joints.

I had contemplated replacing the disks in my 30U Business Coupe and finally found some. They were 5 that were left over from a job that a company in Portland, OR had done some years ago. After I got them I was concerned that they were not machine made and it appeared that they might not balance really well. At that point I decided to look at my options of installing new style U-joints.

I found that with a little research that it was a fairly easy conversion.

I found that with a little research that it was a fairly easy conversion.

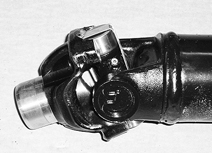

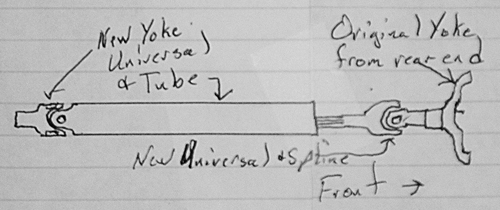

I removed all of the original driveline, including the parking brake system and the rear yoke off the transmission. Then I found that the yoke from the transmission was worn so I took it in to have it built up and resurfaced.

I took the yoke from the front of the differential and used this piece as the front of the new driveline. This yoke can be bolted directly to the yoke on the back of the transmission and the two will hold the original parking brake drum in its original position.

From here back everything is new. They welded a new universal yoke and slip-joint assembly to the front yoke. Then they made a new tube with rear universal and new yoke to fit the differential. The new yoke at the differential solved the problems of wear in the original piece.

From here back everything is new. They welded a new universal yoke and slip-joint assembly to the front yoke. Then they made a new tube with rear universal and new yoke to fit the differential. The new yoke at the differential solved the problems of wear in the original piece.

This job should be able to be done by any competent driveline shop in your local area. Mine was done by Will at Driveline Service of Portland, Inc. You can contact them at 800-227-8608 or www.driveshafts.com.

___________________________________________________________________

Gary (finally) gets a good vibration

Gary Rushers Plymouth runs so smooth, he feels like he has a new car. As we all know Gary has been fighting a vibration problem in his 1930U Coupe for a long time.

He replaced both the front and rear motor mounts with little effect on the vibrations.

After being told that ignition and timing were the problem, he had the valves timed and the distributor rebuilt.

The vibration did not stop and the car acted as if it might be starving for fuel, so he took the carburetor apart and found that the float was improperly set. Fixing it didn’t help.

While looking at the fuel issue he went whole hog, removing, cleaning and sealing the gas tank. A fuel pump rebuild went awry when the company that rebuilt it broke the upper housing, so Gary had got parts from Doug Crawford at Elderly Auto, and rebuilt it himself. It made no difference.

Recently, Pat Brost and Bob Westphal suggested that he should check the ignition again. Maybe one of the springs on the centrifugal advance was bad, or maybe one of the lobes on the distributor shaft was worn.

Bingo! The distributor shaft had a lot of play, allowing the shaft to swing as it rotated, making for very irregular firing. It was a surprise, because the distributor was allegedly rebuilt with new bushings only two years before (by the same company that broke the fuel pump).

Proper repair of the distributor has solved the problem. Gary got new bushings from Doug Crawford at Elderly Auto. Don Ryan made up a nice push shaft and installed the new bushing for Gary. Gary installed the distributor and timed the engine.

A test drive of the car found no engine vibrations and zero lurching. The car runs out nice and smoothly, up to 50 MPH, which was Gary’s limit although he swears the car still had more to give.

It doesn’t drive exactly like a new car, but Gary is happy with the change, and he’s grateful to Pat, Bob and Don for their help and advice.

___________________________________________________________________