Making a fuel tank pan for a

1930 Plymouth U coupe

By Mike Bade

During the time of the Self Distancing, I have been trying to check a few things off my To Do List.

The back of 30 Plymouth, is an area that I have been thinking about for a while. the back of the frame and gas tank area takes away from the finished look of the car when view from the rear, the gas tank is now the most picturesque part of the car.

I see some models of cars that have a nicely designed, Fuel Tank Pan/Cover. I found one years ago I though would fit with a few modifications. I pulled it out of the crawl space and decided it would take a lot of modifying and still would not hide the gas tank and the fuel gauge sender to clean things up.

I see some models of cars that have a nicely designed, Fuel Tank Pan/Cover. I found one years ago I though would fit with a few modifications. I pulled it out of the crawl space and decided it would take a lot of modifying and still would not hide the gas tank and the fuel gauge sender to clean things up.

I watch all these car restoration shows and I thought I could, come up with something, if I just tried. I dug out some Foam Core Mounting Board I use for my photography. I measured and cut a pattern, trying to make it in one piece since I do not have a welder and having something welded would cost lots. I cut relief cuts so I could follow the curve of the stock frame; something that could be curved on a "slip roller" and then would have a radius bend that could bent, in small steps using a "sheet metal break".

The pattern quickly came together, but it did not have much stability, maybe I could save money and fiberglass it I thought. I nixed that Idea quickly, pretty messy and in the long run could be cracking etc.

I decided, it had to be made from steel an a more accurate pattern was needed. I had some door panel board that would make a more accurate and refined pattern and then take to a company and fabrication. Yup the plan to make the fuel tank pan looked pretty good and all I had to do was find someone to make it happen.

I decided, it had to be made from steel an a more accurate pattern was needed. I had some door panel board that would make a more accurate and refined pattern and then take to a company and fabrication. Yup the plan to make the fuel tank pan looked pretty good and all I had to do was find someone to make it happen.

I took my pattern to 5 different fabrication companies and was turned down, not having the proper equipment. I thought I could take it to a restoration shop, they certainly would have the equipment, right: no, but I did get a lead on where I could get the job done.

I went to Versa-Tech Metal Fab, Inc. in North East Portland, I drove my 30 Ply Coupe and took my pattern, to the man how pattern fit and what I needed and he assured me they could do the job. Five days later I had my fuel tank pan, I only had to do a little tweak I had not considered, but I had it fixed in short order.

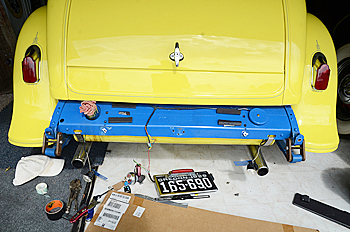

The next step was to locate the mounting holes, holding it in place and marking the four holes that would hold it in place. Fortunately there were pre-drilled holes in the frame that made it easy. A trip to Parkrose Hardware and $32.00 later I had fresh mounting and assorted bolts that I would need. A little grinding where the gas tank filler came through and It was ready for paint.

The next step was to locate the mounting holes, holding it in place and marking the four holes that would hold it in place. Fortunately there were pre-drilled holes in the frame that made it easy. A trip to Parkrose Hardware and $32.00 later I had fresh mounting and assorted bolts that I would need. A little grinding where the gas tank filler came through and It was ready for paint.

I worked the metal over to prep for primer and paint, I went to Industrial Finishes and had a fresh pint of color mixed and two rattle cans and primer. I made quick work of the painting, of course you have to wait between coats of paint, that drags things out and you have to paint a both sides.

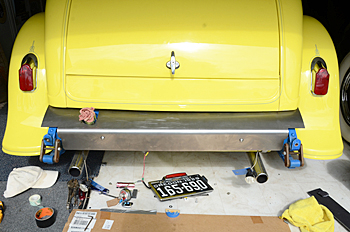

The powder coated bumper was blocking the new paint in the fuel tank pan, I prepped it also and painted yellow to match.

Then there was remounting if the rear backup lights. I had used some holes on the old frame crossbar and had to modify there mounting to keep things clean. Similarly, the rear license plate needed a new mounting place, it was also mounted on the old frame cross bar. I scavenged some metal and tweaked it a little, drilling and painting and then ready.

I think the results are significant, cleaning up an area that will make my car looking more finished and closer to being finally done, if any car is ever done.